|

SHOP BY

PRODUCT

(Alpha Order)

ABRASIVES

ZEK DISCS

WIRE WHEELS

METAL POLISHING

SEALANT CUT-OUT

AIR

SCRUBBERS

VENTILATORS

ANCHORS,

EPOXY

MASONRY

MADE TO PRINT

STRUT, FITTINGS

CARBIDE,

CHISELS

DUST CONTROL

CUSTOM LENGTHS

DIAMONDS

GRINDER

PACKAGES

DESIGN

& BUILD

METAL FABRICATION

DUST

EXTRACTORS

ACCESSORIES

HEPA VACUUMS

DUST

FANS

VENTILATION

CONTAINMENT

ENCLOSURES

RAM BOARD, TAPE

PLASTIC SHEETING

FLOOR

GRINDERS

GRIND / POLISH

COATING REMOVAL

GANG

BOXES

GENERATORS

INVERTERS

LADDERS

PRESSURE

WASHERS

RECOVERY

SLURRY

VACUUMS

PRESS MACHINES

SURFACE

PREP

FLOOR GRINDERS

DIAMOND TOOLING

| |

|

Design

& Manufacturing Solutions Industrial,

Continuous-Duty Dust Extractors

|

|

Custom Solutions

--- Construction,

Industry, Manufacturing, OEM.

Need

help upgrading your dust

extraction operation? Improving performance, efficiency, safety,

working conditions?  Tired

of wasting time and money on shop vacuums? Is dust eating them up

and the motors not lasting? All applications or

operations have some degree of delimiting factors and we analyze and

consider all of them including price. Tired

of wasting time and money on shop vacuums? Is dust eating them up

and the motors not lasting? All applications or

operations have some degree of delimiting factors and we analyze and

consider all of them including price.

As experts in our field

we realize that many of you are not aware of what can be done or is

available ... Common areas that we address include:

- longer life

motors, circuit boards, hoses

- better filtration

to reduce suction drop, less maintenance, cleaner exhaust, improved separation

- greater power

with

reduced amp draw, quieter operation

cleaner and safer

handling and disposal of debris, reclamation of product cleaner and safer

handling and disposal of debris, reclamation of product- stationary,

wall mount or mobile design

- versatility to handle multiple

applications or to also be used to vacuum spills, industrial cleaning,

etc.

- sequential timing

to operate multiple work stations or milling machines (ref. above

photo), etc.

With any number of

reasons to have a better vacuum system, including:

- tighter EPA and

OSHA regulations

- production

demands

- better and safer

working conditions

- to compliment your premier OEM

product with a superior vacuum.

Please

feel free to give us a call to see what we can do for you.

|

|

AVENGER

- Industrial Vacuums AVENGER

- Industrial Vacuums

Maximize

Performance, Production, Safety, Profits

--------

With a Custom

Designed Industrial-Grade Dust Extractor

|

|

- 120 Volt, 13.8 Amp

- 440 CFM, 110"

H20

- Semi-Automatic

Filter Cleaning

|

- 240 Volt, 7.0 Amp

- 350 CFM, 110"

H20

- Automatic Filter

Cleaning

|

|

Continuous

Duty Industrial Vacuum Cleaners

for Fine Combustible Dusts |

|

|

Safety

Consideration - Combustible

Dust

Is

there a possible threat of a combustible dust explosion at your

facility?

-

Do

you use vacuum's with carbon brushes at your work stations?

-

Are

you constantly replacing motors?

-

Are

you aware of the dangers of dust accumulation?

| OSHA

estimates that over 30,000 U.S. facilities, in all types of

industries, are at risk everyday for a major combustible dust

explosion. The threat of an industrial explosion in your

facility is very real.

Combustible

dust can explode like gunpowder, if let to accumulate it

could explode . . .

Don't underestimate its devastating

consequences . . .

For this reason OSHA recommends and

in some cases requires the use of an explosion proof vacuum as part of their

regular plant maintenance or housekeeping program. |

Is

combustible dust present in my company?

If dust accumulations cover 1/32"

on 5% of

the floor, then "yes" - combustible dust is in your

company.

OSHA

& Combustible Dust Enforcement.

Are you doing

enough?

OSHA

& Combustible Dust Enforcement.

Are you doing

enough?

Definition of

Hazardous Locations, Types of Dust?

National

Electric Code (NEC) Classifications:

National

Electric Code (NEC) Classifications:

Different

types of dust - is the dust you create combustible, as defined by

OSHA?

OSHA's Policy

& Inspection Procedure to handle combustible dust.

OSHA

Combustible Dust Directive CPL 03-00-008 / Emphasis Program. OSHA's

policy and procedures for inspecting a workplace pertaining to the

creation and handling of combustible dusts.

OSHA

Combustible Dust Directive CPL 03-00-008 / Emphasis Program. OSHA's

policy and procedures for inspecting a workplace pertaining to the

creation and handling of combustible dusts.

|

|

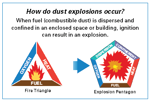

What

Causes a Combustible Dust Explosion? |

|

There is a risk of explosion when any five of the fire and

explosion elements are present: There is a risk of explosion when any five of the fire and

explosion elements are present:

If you can eliminate the

dust

you can eliminate the explosion hazard . . . If you can eliminate the

dust

you can eliminate the explosion hazard . . .

During plant

maintenance, the traditional practice of sweeping or blowing will actually

increase your chance of a combustible dust explosion.

|

|

Steps to Reduce

a Combustible Dust Explosion? |

|

Being

aware of the situation and addressing it is the first step.

A key element here is to eliminate open electrical boxes. Being

aware of the situation and addressing it is the first step.

A key element here is to eliminate open electrical boxes.

If all of your metal

equipment is properly bonded, you effectively eliminate the static

discharge in your system and you won’t have a credible ignition

source.

Capturing

dust at its source is both the immediate and long term

answer. In many situations, this is best accomplished using

a well designed dust extractor.

Once

installed, proper maintenance

of the equipment and the area to keep them clean and reduce dust

build-up is the next step. This good housekeeping practice

is best accomplished using a non-conductive, 100%

grounded, industrial vacuum. In

many cases, such as with the B1000, the same vacuum can be used.

In contrast, vacuums

with carbon-brush motors, non-conductive on/off switches and metal

parts could be the igniter that actually causes the explosion by producing a spark

(electrical or static).

Simply put, when it comes to

safe plant operation and

maintenance, not just any vacuum will do . . .

|

|

|

AVENGER

- Industrial Vacuums

AVENGER

- Industrial Vacuums