|

SHOP BY

PRODUCT

(Alpha Order)

ABRASIVES

ZEK DISCS

WIRE WHEELS

METAL POLISHING

SEALANT CUT-OUT

ANCHORS,

EPOXY

BUY AMERICAN ACT

- DOT APPROVALS

MASONRY

MADE TO PRINT

STRUT, FITTINGS

CARBIDE,

CHISELS

DUST CONTROL

CUSTOM LENGTHS

DIAMONDS

GRINDER

PACKAGES

DESIGN

& BUILD

METAL FABRICATION

DUST

EXTRACTORS

ACCESSORIES

HEPA VACUUMS

DUST

GUARDS

TUCK POINTING

SURFACE GRINDING

ELECTRICAL

GENERATORS

1& 3-Phase

CORDS, 600V WIRE

FANS

VENTILATION

CONTAINMENT

FLOOR

GRINDERS

GRIND / POLISH

COATING REMOVAL

GANG

BOXES

LADDERS

SLURRY

SQUEEGEES

PUMP-OUT VACS

PRESSURE WASHERS

SURFACE

PREP

CONTAINMENT

FLOOR GRINDERS

FANS, VENTILATION

PLASTIC SHEATHING

| |

|

Additional

Information

|

Benefits

|

|

|

ELIMINATE

REGULATORY CONCERNS

With

increased EPA enforcement of industrial suspended solids many

contractors have been hit recently with large fines. Most

contractors are unwilling to carry the huge financial risk and

liability associated with not cleaning their water. Some

contractors have left the efficiency of wet grinding and face

new operational difficulties with dry grinding.

The

MudHen eliminates your financial liability over regulatory

concerns potentially saving you thousands of dollars, allowing

for water reuse and recycling on site.

|

|

Applications

|

MudHens

can solve a variety of slurry water issues for different

applications. They are commonly used on stone, ceramic

and glass slurry as well as other slurries that have a high

quantity of suspended solids.

|

|

|

|

|

| Fabrication

Plants |

Walk-Behind

Saws |

Masonry

Saws |

Concrete

Slurry |

Slurry

waters can be effectively treated to be EPA (Environmental

Protection Agency) compliant. Pump trucks, stone and

tile saws, cement and mortar mixers along with industrial

slurries can be treated to remove the vast majority of

suspended solids. The pH can easily be treated to meet

EPA requirements.

The

recycled water can be reused on site to reduce water

consumption. The sludge is collected and compacted for

easy disposal.

For

years concrete wash out slurry has been a challenge.

With a MudHen concrete washout system compliance has never

been easier. All MudHen products are made in the USA.

Application:

Concrete Washout ---

Concrete, Terrazzo, Paint, Stucco, Mortars, Grout, Stone,

Tile, Glass, etc.

| SLURRY

SOLUTIONS - INDUSTRIES

WE SERVE |

| MINING

& FRACKING |

CONSTRUCTION

& INDUSTRIAL |

METAL

& METAL FINISHING |

| READY

MIX WASHOUT |

CONCRETE

POLISHING |

GRANITE

&

STONE FABRICATION |

| FOOD

& BEVERAGE |

MASONRY

&

CONCRETE SAWING |

WATER

JET BLASTING |

| PRE-CAST |

PETROLEUM |

CHEMICAL |

| MUNICIPAL |

GLASS |

CEMENT |

|

|

|

Sizing - What size

press do I need?

|

|

If

you’re working in an industry where wastewater is a

byproduct, you’ll need an effective method to treat the

slurry water. A filter press is the perfect solution,

but it isn’t just one size fits all. If

you’re working in an industry where wastewater is a

byproduct, you’ll need an effective method to treat the

slurry water. A filter press is the perfect solution,

but it isn’t just one size fits all.

It’s

important to consider size before investing in a filter

press. It’s easy to simply choose the biggest option

and assume the filtration process will go smoothly as long as

it isn’t overloaded. But bigger is not always better so

you should choose a filter press after carefully considering

your needs and the application you are using it for.

In

certain applications, cake and water quality can drop if the

press is oversized. Additionally, a filter press than is

too large can make your costs rise, not only with the initial

purchase but when running the machine. Thoughtful design

and pairing with other technologies can reduce the size and

overall cost of your purchase.

BUYING

DECISION - Which Mudhen to Purchase?

Factors

to Consider:

-

How

many gallons of slurry do you need to process per day?

The quantity of solids

that are in the slurry? --- Slurry with less solids

require less filter chambers. -

PATIENCE

or SPEED? For

slurry with more solids, although all the Mudhens will

do the job, the more collection chambers there are the less time

you'll spend separating and emptying them. For

example, to process 500 gallons

of concrete slurry per hour you'll want to go with a larger

filter press (MH1 or MH2), otherwise you'll be spending

too much time manning the machine (i.e. emptying

plates).

-

Mudhen

Size & Weight - although all 4-Mudhen models are

portable, the Mini and MH1 are smaller and weigh less so

they may be better suited for maneuvering within job

constraints.

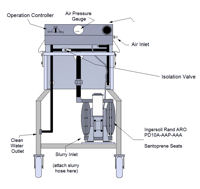

COMPRESSOR

SIZE - Air Requirements

-

Dry

filtered air is required to minimize the maintenance on

the system

-

MudHens

can be adjusted to effectively operate in a wide range

of locations and conditions. Minimum CFM is 5,

ideally: 10 CFM. MudHens

can be adjusted to effectively operate in a wide range

of locations and conditions. Minimum CFM is 5,

ideally: 10 CFM.

-

MudHens

are equipped with an air operated diaphragm pump - this

pump requires a minimum of 5 cfm of air to operate with

a tank size between 15 and 30 gallons (an air compressor

with a 15-gallon tank is the

smallest size tank that can operate a MudHen)

-

RECOMMENDED

COMPRESSOR - Mudhens run best using a 15 / 30-gallon air

compressor set between 50 and 80 PSI - see Dewalt

D55168 Compressor (right.) Once properly

adjusted to your filtration requirements and processing

times, the Mudhen may be left to operate

unattended. For crystal clear water output,

efficiency of operation and fast processing times set

the compressor at 50 PSI and adjust it upwards to a

maximum of 80 PSI.

If

you have any questions and are pondering what size or

additional components you may need, please call us - we'll be happy to assist

you: 412

- 605 - 2992.

|

|

|

|

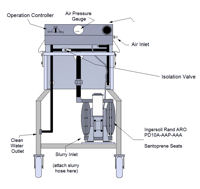

Operation

|

-

Connect

air compressor hose to Mudhen air fitting

-

Place

slurry line and screener (included) into the container of

slurry

-

Attach

output hose and secure the hose into the container that the

clarified water will flow in

-

Adjust

regulator on Mudhen control panel to 30 PSI

-

Turn

operation controller "on" – the Mudhen will

begin to pump slurry through the unit

-

As

back pressure builds in the Mudhen and the pump slows,

adjust PSI regulator upwards in 20 pound increments.

This is done up to 80 psi, do not and never exceed 80 PSI.

-

Eventually

the Mudhen's pump will stall or you'll hear it trying to

gulp for slurry, this is the indication that the collection

chambers are full of solids or the slurry container is empty

(the pump will not be harmed as it gulps for more slurry to

process.)

|

|

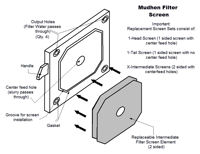

Leaking

Plates

|

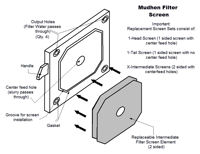

Pre-Coating

the Filter Cloths. If

the plates leak while pressure builds, apply more pressure via

the hand jack. Each filter plate or chamber includes (20

filter media cloths with a filter efficiency rating of 5

microns.

The

filter cloths require solids in your slurry to ensure the

efficient operation of a Mudhen (i.e. the chambers will leak if

drinking water is pumped through them.)

Pre-coating

the filter cloths increases their efficiency rating to 1 to .6

microns

Pre-coating

the filter cloths should be your 1st step to ensure the purity

of the liquid being discharged.

|

|

PRE-COAT

STEP

"GO

SLOW & LONG ENOUGH"

This

step is only for the first filling of the plates. After

the initial release of your first cakes you'll still start the

Mudhen slowly (10 PSI), but only for a few minutes as the filter

cloths are already coated.

As

you observe the clarity of the water being discharged, the PSI

may be gradually increased to the optimal operating setting

between 50 and 80 PSI.

|

Two

(2) Pre-Coat

Methods:

-

Loading

Method - Using your own sediment. Start the Mudhen at

the slowest speed possible (1 - 10 PSI). Depending on

the particle size and volume of sediment in your slurry,

pre-coating times will vary (2 to 40 minutes).

-

Mix

Method - Mix 20 lbs. of diatomaceous earth (or perlite or dicalite)

with 10 gallons of water. Pump this milkshake mixture

through the filter chambers to instantly pre-coat the filter

cloths. You may immediately being normal operation of

the Mudhen using its optimal operating speed of 80 PSI.

Once

the filter cloths are properly coating (as determined by the

purity of the water being discharged), you can increase the PSI

into the press.

If

the water being discharged ever begins to look cloudy simply

reduce the PSI to the pump. This will slow down the intake

of slurry going into the filter chambers while it continues to

pre-coat the filter cloths. Additionally, if speed isn't

too important you can leave the machine operating slowly (i.e.

50 PSI).

|

Caked Solids

Emptying

the filter chambers and dropping the caked plates.

The

powerful 3/4" diaphragm pump (completely adjustable, 0 - 30

GPM or 0 - 100 psi of air) will push and compact the solids in

the filter chambers.

The

filter chambers, held in place within the heavy framework of the

Mudhen, are pressed together with 5000 lbs. of force from the

hydraulic hand pump.

As

the filter chambers fill, pressure gradually increases and the

purity of the liquid being discharged also improves as the

solids fill within the filter chambers.

Once

full (the liquid being discharged will cease to flow), operator

intervention is required to release the dry the caked plates and

empty the chambers.

As

each filter chamber is separated, the caked plates are released

and dropped into the collection tray or a wheel barrel.

|

Drying / Cleaning

Procedure:

- Remove

slurry line from sludge and allow pump to pump air for a

minimum of 5 minutes (the longer it operates the drier the

cake)

- Turn

operation controller to off, adjust air to 30 psi

- Turn

operation controller to dry

- Turn

isolation valve “A” located right below controls to its

off position (ref Operation drawing, above)

- This

will allow more air to travel through the plates

- Water

will sputter out of the output hose

- After 2

minutes open the isolation valve “A”

- Turn

the operation controller to off

- Loosen

the hydraulic jack pressure relief valve

- Separate

the chambers and clean the screens with the enclosed scraper

- After

every 1 to 4 weeks depending on the nature of the slurry –

pressure wash the plates & cloths to ensure open and

clean pores for proper filtering

- DO NOT

LEAVE SOLIDS IN THE MUDHEN FOR MORE THAN 1 TO 2 DAYS –

DOING SO CAN RUIN THE SCREEN CLOTHS INSIDE THE SYSTEM.

END of DAY

CLEANING

At the end of each day

of use it is important to flush out any slurry from the

system. This includes flushing the air pump and the

filtration plates as well as any hoses. This can be done

by directing the clean water discharge hose from the system and

running its clean water right through the Mudhen.

|

|

|

|

|